Pickling stainless steel

Pickling is a surface treatment process for metals. This process is used to ensure the corrosion resistance of stainless steel and thus makes a decisive contribution to increasing the service life of the workpieces made from it and increasing their usefulness.

The reason for this effect is the intensive cleaning and activation of the metal surface, with both processes taking place simultaneously during pickling. What remains is a metallically pure surface free of oxides and contamination from foreign metals.

However, slight material erosion can rarely be avoided. Pickling gives the surfaces a matt, silky gloss appearance.

During the pickling process, a chemical mixture, the pickling agent, attacks the grain boundaries of the metal structure.

The pickling agent usually consists of a mineral acid mixed with an oxidizing agent.

There are also other additives which optimize the result of the pickling process and also reduce pollutants.

Depending on requirements, the process can also be carried out electrolytically (anodically) in addition to the pickling agent. The applied electrical voltage supports the pickling process.

We have a tank with useful dimensions of 1200 x 700 x 500 mm for carrying out the pickling process, which we are happy to make available to you.

It goes without saying that the workpieces to be processed by us must not exceed the dimensions of our tank.

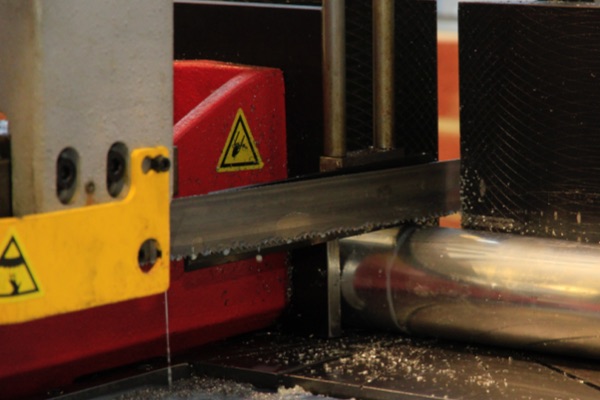

Impressions

We are happy to help you

- Consulting and development

- Budget and schedule planning

- Supplier selection, purchasing and quality control

- Assembly and prefabrication

- Documentation

- Process support

- Maintenance, servicing and revision

Our service for you

We advise you from planning and maintenance to commissioning.

We work with you to develop the best possible process solution for your requirements.

Contact form