Wolframelektroden

Wir stellen Wolframelektroden für das Orbitalschweißen und das WIG-Schweißen her. Die Elektrodenlänge kann zwischen 8,0 mm und 175,00 mm betragen. Ständige Qualitätsprüfungen garantieren eine gleichbleibende Präzision in der Fertigung. Elektroden sind frei von Thoriumdioxid und damit nicht radioaktiv und nicht krebserregend.

Allgemeines zu Wolframelektroden

Wolframelektroden werden vor allem zum Wolfram-Inertgasschweißen (WIG-Schweißen) als auch beim Orbitalschweißen benötigt. Dabei handelt es sich um reine oder mit oxidischen Zusätzen versehene Elektroden. Eine farbliche Kennzeichnung erhalten sie oft nach Zusatz-Art und Menge.

Die Qualität von Schweißelektroden wird in erster Linie von der Strombelastung während des Schweißvorganges, von der Güte der Schweißnaht sowie vom Verhalten der Elektrode während der Standzeit bestimmt. Die Strombelastung einer Elektrode ist von ihrem Durchmesser, der Stromart und der Polung, den verwendeten Legierungszusätzen der Elektrode sowie dem Anschliffwinkel abhängig.

Die Güte der Schweißnaht bemisst sich vor allem an der Form der Elektrodenspitze. Elektrodenspitzen ohne Risse erreicht man am besten durch das Schleifen mit einer möglichst feinen Körnung. Dadurch erhöht sich gleichzeitig auch die Standzeit der Elektrode.

Schweißen mit Thoriumdioxid:

Elektroden mit einem kleinen Thoriumanteil werden häufig für das Gleichstromschweißen von rostfreien und hochlegierten Stählen verwendet. Der Anteil an Thorium bewirkt, dass beim Schweißen weniger Elektronen austreten. Das Oxid verbessert damit die Elektronenemission. Dafür werden Elektroden mit unterschiedlichem Thoriumanteil hergestellt. Je mehr Thorium in der Elektrode enthalten ist, desto deutlicher verbessern sind die Zündeigenschaften, die Standzeiten und die Strombelastbarkeit beim Gleichstromschweißen. Thorium ist ein natürliches radioaktives Element. Wenn es zerfällt, bilden sich weitere radioaktive Produkte. Die Gefahr bei den thorierten Elektroden durch die freiwerdende Gammastrahlung ist zwar gering, gefährlicher wirkt sich jedoch die Alphastrahlung aus.

Schweißen ohne Thoriumdioxid:

Die Entwicklung von nichtthorierten Elektroden ist mittlerweile so weit fortgeschritten, dass ein Einsatz von thorierten Elektroden nicht mehr notwendig ist. Als Alternative bieten sich hier, neben cerierte und lanthanierte Elektroden, auch Orbital Elektroden an. Orbital Elektroden bestehen aus Beimengungen von Mischoxiden mit unterschiedlicher Zusammensetzung. Beispielsweise glänzen längsgeschliffene Orbital Elektroden mit hoher Standzeit und Belastbarkeit.

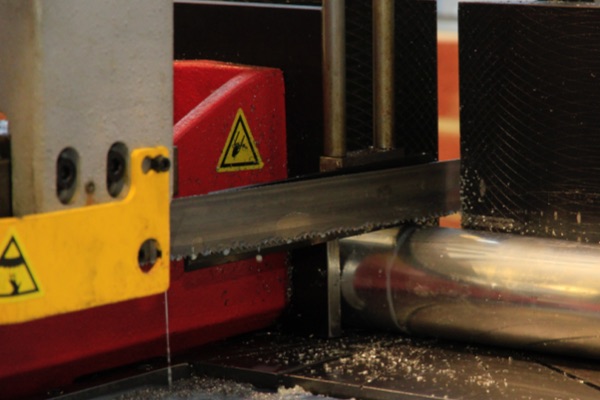

Impressionen und Eindrücke

Wir helfen Ihnen gerne

Wartungs- und Servicekonzepte bei Ihnen im Haus oder für Ihr Projekt. Vor Inbetriebnahme Ihrer Anlage entwickeln wir notwendige Wartungskonzepte für einen problemlosen Betrieb.

- Beratung und Entwicklung

- Budget- und Terminplanung

- Lieferantenauswahl, Einkauf und Qualitätskontrolle

- Montage und Vorfertigung

- Dokumentation

- Prozessbetreuung

- Wartung, Instandhaltung und Revision

Unser Service für Sie

Wir beraten Sie von der Planung, Instandhaltung bis zur Inbetriebnahme.

Gemeinsam mit Ihnen entwicklen wir die bestmögliche Prozesslösung für Ihre Anforderungen.

Zum Kontaktformular