Orbitalschweißen

Beim Orbitalschweißen wird der Schweißkopf mechanisch in einer Halterung (dem Kopf) um den Schweißkörper herumgeführt und dabei die Nahtstelle in einem Durchgang ohne Unterbrechung zusammengeschweißt.

Mittels Schutzgas werden dabei der Lichtbogen und die Nahtstelle vor der Außenluft geschützt. So wird eine exakte Kontrollierbarkeit der Nahstelle erreicht und die Anlauffarben sowie die Wurzel der Schweißnaht lassen sich gut beeinflussen. Dadurch kann eine gleichbleibend hohe Qualität der Naht sichergestellt werden.

Weitere Vorteile sind unter anderem die hohe Sicherheit des Verfahrens, die hohe Reproduzierbarkeit der Schweißergebnisse, die kurze, und sehr wirtschaftlich Produktionszeit und die Dokumentationsfähigkeit des Schweißvorgangs nach ISO 9000.

Die Orbitalschweißtechnik kommt hauptsächlich im Rohrleitungs- und Kesselbau und bei Steril- und Reinstmedien in der Chemie-, Pharma-, Halbleiter-, Getränke- und Nahrungsmittelindustrie zum Einsatz, da es eine einheitliche und damit den hygienischen und technischen Anforderungen entsprechende Ausführung von Schweißnähten bietet.

Für Ihre Anfrage benötigen wir folgende Daten:

Gute Dokumentierbarkeit

Durch das Schweißgerät, das durch einen Mikroprozessor gesteuert wird, werden alle wichtigen Parameter des Schweißvorgangs aufgezeichnet und dokumentiert. Der Restsauerstoffgehalt kann nach Abschluss der Arbeit ebenfalls gemessen und dokumentiert werden.

Dadurch können auch hohe Ansprüche an die Dokumentation des ganzen Arbeitsvorgangs erfüllt werden.

Unsere Dienstleistungen

Unsere Firma ist Spezialist im Orbitalschweißen und beschäftigt nach DIN EN 1418 bzw. neue Norm DIN EN ISO 14732 geprüfte Orbitalschweißer.

Unsere Mitarbeiter sind hoch qualifizierte Anlagenmonteure, die über eine langjährige Erfahrung in der Montage von Rohrleitungen verfügen.

Zudem sind sie ebenso qualifizierte WIG Handschweißer nach DIN EN 287-1 und Vorrichter nach ISO. Die Mitarbeiter haben wir selbst in internen Schulungen zum Orbitalschweißer weiterqualifiziert.

Durch unser geschultes Personal und automatisierte Verfahren beim Orbitalschweißen erreichen wir eine Optimierung der Schweißzeiten, und können damit alle Arbeiten schnell und kostengünstig ausführen.

Das führt insgesamt zu einer hohen Wirtschaftlichkeit des gesamten Prozesses.

Unsere Geräte

Für unsere Arbeit setzen wir die Geräte der bekannten Hersteller AMI/ARC, Swagelok, Orbitalum, Polysoude und Fronius ein, die sich durch den hohen Qualitätstand ihrer Orbitalschweißtechnik bereits einen Namen gemacht haben.

Durch unsere mobilen Orbitalschweißanlagen und -geräte sind wir in der Lage, unsere Dienstleistungen vor Ort auf allen Baustellen anzubieten. Daneben verfügen wir über eigene Fertigungshallen, in denen größere Werkstücke in unseren Schweißanlagen zusammengefügt werden können. So können wir ein komplettes Dienstleistungsangebot rund um das Orbitalschweiß- und andere Verfahren anbieten

- ORBIMAT 180 SW Orbitalschweißstromquelle: 6 Stück

- ARC 207A Orbitalschweißmaschine: 24 Stück

- ARC 307A Orbitalschweißmaschine: 6 Stück

- ARC 205 Orbitalschweißmaschine: 1 Stück

- ARC M217P Orbitalschweißmaschine: 5 Stück

- Swagelok M100 Orbitalschweißmaschine: 12 Stück

- Swagelok M200 Orbitalschweißmaschine: 7 Stück

- Polysoude Orbitalschweißmaschine: 1 Stück

- Orbitalschweißköpfe: 8-4000, 8-2000, 9-7500, 9-4500, 9-4500, 9AF-750, 9-500, 9-500 c, 95-2375, 95-3500, 95-6625, Swagelok Cajon Schweißkopf 5H – B, Swagelok Cajon Micro-Schweißkopf 8MRH, ORBIWELD 12, ORBIWELD 19, ORBIWELD 38S, ORBIWELD 76S, ORBIWELD 115 S

- Durchmesser: ≥ DN10

- Wandstärke: ≥ 1 mm

- Vorteile: Reproduzierbarkeit der Schweißnähe, gleichbleibende Qualität, hohe Ansprüche an die Dokumentation werden erfüllt

- Werkstoffe: Edelstahl, Titan und Stahl

Als qualifizierter Schweißfachbetrieb bieten wir Ihnen neben professionellen Schweißdienstleistungen in unseren Fertigungshallen auch einen Personalservice in Form von Arbeitnehmerüberlassung im Anlagenbau und Rohrleitungsbau, Montage und Engineering Unternehmen weltweit an, die höchsten Sicherheitsanforderungen und Ansprüchen genügen.

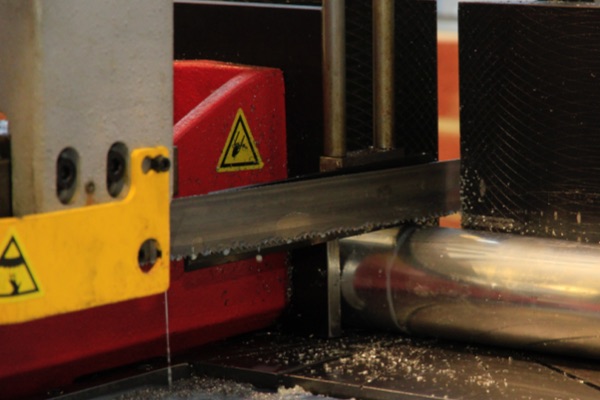

Impressionen und Eindrücke

Wir helfen Ihnen gerne

Wartungs- und Servicekonzepte bei Ihnen im Haus oder für Ihr Projekt. Vor Inbetriebnahme Ihrer Anlage entwickeln wir notwendige Wartungskonzepte für einen problemlosen Betrieb.

- Beratung und Entwicklung

- Budget- und Terminplanung

- Lieferantenauswahl, Einkauf und Qualitätskontrolle

- Montage und Vorfertigung

- Dokumentation

- Prozessbetreuung

- Wartung, Instandhaltung und Revision

Unser Service für Sie

Wir beraten Sie von der Planung, Instandhaltung bis zur Inbetriebnahme.

Gemeinsam mit Ihnen entwicklen wir die bestmögliche Prozesslösung für Ihre Anforderungen.

Zum Kontaktformular